The construction sector is increasingly aware of the importance of energy efficiency and sustainability. In this context, a good choice of insulated pipes is essential.

These types of pipes not only offer immediate benefits in terms of performance and durability, but also meet the growing demand for more environmentally friendly construction and operating practices.

In this article, we will explore the various applications of pre-insulated pipes, along with their installation, maintenance and the technological advances that are defining their present and future.

- What are pre-insulated pipes?

- Benefits of pre-insulated pipes

- Pre-insulated pipe applications

- Areas where pre-insulated pipes can be installed

- How to choose the right pre-insulated pipe

- Regulations: RITE, Reglamento de Instalaciones Térmicas de los Edificios

- Installation and maintenance of pre-insulated pipes

- Technological advances in insulated pipes

What are pre-insulated pipes?

Pre-insulated pipes are an innovative and efficient solution in the world of construction and engineering. These are complete fluid transport systems consisting of a carrier pipe (also known as a service pipe or inner pipe), insulation material and an outer casing.

These pipes are designed to transport liquids, such as hot water, steam or cold liquids, minimising heat or cold losses in the process. They are the most efficient solution for application in installations where insulation is required.

Benefits of pre-insulated pipes

Pre-insulated pipes are a great choice in terms of efficiency and performance in a variety of industrial, commercial and urban applications. The following are some of its benefits:

- Energy efficiency: Integrated insulation significantly reduces heat or cooling losses, resulting in lower energy consumption and reduced operating costs.

- Durability and strength: Pre-insulated pipes, especially those made of polypropylene, are known for their resistance to corrosion and their ability to withstand harsh environmental conditions, ensuring a long service life of the piping system.

- Ease installation: As prefabricated systems, pre-insulated pipes are easy to transport and install. This reduces installation times and labour costs, streamlining the construction process and improving the profitability of projects.

- Adaptability to the environment: Pre-insulated pipes are versatile and adapt to a variety of environments. They are suitable for both indoor and underground installations, as well as for outdoor applications due to their resistance to UV radiation.

- Low thermal conductivity: The low thermal conductivity of the insulating material used in pre-insulated pipes ensures excellent temperature retention. This minimises heat or cooling losses during fluid transport, ensuring better thermal performance and energy efficiency.

- Reduced environmental impact: The use of pre-insulated pipes contributes to the sustainability of construction projects by reducing energy demand and, consequently, greenhouse gas emissions. In addition, by minimising heat and cooling losses, natural resources are saved and the environmental impact is reduced.

Pre-insulated pipe applications

Pre-insulated pipes have a wide range of applications due to their energy efficiency and their ability to maintain a constant fluid temperature. Its use is notable in the following areas:

- Heating and cooling systems: Pre-insulated pipes are ideal for heating and cooling systems in residential, commercial and industrial buildings. Their ability to minimise heat loss and maintain a constant fluid temperature allows for efficient operation and energy savings in these installations.

- Energy distribution networks: Pre-insulated pipes are widely used in energy distribution networks, such as steam and hot water systems, where it is essential to maintain temperature and energy efficiency over long distances.

- Geothermal power plants: These pipes are an optimal solution for geothermal power plants, where the transport of hot fluids from underground to the surface requires efficient and durable thermal insulation.

- Industrial processes: In industrial environments where fluids are handled at controlled temperatures, such as in the chemical or food industry, pre-insulated pipes ensure safe and efficient transport.

- Tunnels and bridges: In infrastructure projects such as tunnels and bridges, pre-insulated pipes are ideal for transporting fluids along underground or elevated structures, minimising energy loss and ensuring optimum performance.

Areas where pre-insulated pipes can be installed

Because this type of pipe is appropriate for both indoor and outdoor or buried installations, its versatility makes it suitable for a multitude of spaces, among them:

- Residential and commercial buildings

Pre-insulated pipes are a smart choice for heating and domestic hot water needs.

In residential buildings, these pipes are easily integrated into central heating systems, providing uniform and efficient heat throughout the home.

In the commercial field, they are ideal for hotels, hospitals, shopping centres and other mixed-use buildings where reliable, low-maintenance hot water distribution systems are required.

- Industrial installations

In demanding industrial environments, such as production plants or data centres, reliability and durability are paramount. Specifically, pre-insulated polypropylene pipes offer a reliable and durable solution for the transport of fluids in critical infrastructure.

- Urban infrastructure

In urban development projects, pre-insulated pipes play a key role in improving the energy efficiency and sustainability of urban infrastructure.

In the expansion of district heating networks, these pipes facilitate the efficient transport of heat over large distances, reducing energy losses and improving the thermal comfort of residents.

In addition, in the modernisation of water distribution systems, pre-insulated pipes help to minimise leakage and heat loss, thus contributing to the conservation of resources and the reduction of long-term operating costs.

How to choose the right pre-insulated pipe

Selecting the appropriate type of pre-insulated pipe is crucial to ensure optimal performance and durability of the system. For this, it is essential to consider a number of key issues.

First, it is necessary to assess the specific temperature and pressure conditions to which the pipe will be exposed. This will allow the selection of a material and insulation thickness that can adequately withstand these conditions, ensuring efficient operation and a long service life.

The pipe and insulation material also plays a key role. Polypropylene stands out thanks to its corrosion resistance and durability. The combination of the pipe material with appropriate thermal insulation ensures efficient fluid conduction and adequate protection against heat or cold loss.

It is also important to comply with local regulations and industry standards when selecting and installing pre-insulated pipes. Working with qualified suppliers and professionals ensures compliance with regulatory requirements and the quality of the installed system. This includes following specific guidelines related to installation, handling and safety to ensure a smooth process and a safe and reliable end result.

Finally, it is essential to assess the environmental impact of pre-insulated pipelines. Selecting recyclable materials and energy-efficient systems helps to reduce the environmental footprint of the project. In addition, choosing materials and installation methods that minimise waste and pollution promotes the long-term sustainability of the project and the surrounding environment.

Considering the environmental impact of pre-insulated piping allows an informed decision to be made that promotes environmental responsibility and energy efficiency in the project.

Regulations: RITE, Reglamento de Instalaciones Térmicas de los Edificios

The RITE (Regulation of Thermal Installations in Buildings) is the regulation that governs the conditions that heating, air-conditioning and domestic hot water installations, equipment and systems have to meet, in order to achieve a rational use of energy, while at the same time satisfying the demand for thermal comfort and hygiene.

This regulation came into force in 2007, through Royal Decree 1027/2007 of 20 July 2007, and is therefore mandatory. A major modification of the RITE in 2021 has led to an increase in energy efficiency requirements in order to meet the climate targets of the National Integrated Energy and Climate Plan 2021-2030 (PNIEC).

The sections included in the RITE include Technical Instruction IT1, where pipe insulation is considered.

TECHNICAL INSTRUCTION IT.1 DESIGN AND SIZING

IT 1.2.4.2 Pipe networks and ducts

IT 1.2.4.2.2.1 Thermal insulation of pipe networks

IT 1.2.4.2.2.1.1.1 General

- All pipes and fittings as well as equipment, appliances and tanks of thermal installations shall be provided with thermal insulation where they contain thermal insulation:

a) refrigerated fluids with a temperature lower than the ambient temperature of the room through which they flow;

b) fluids with a temperature higher than 40 ºC when installed in unheated premises, including corridors, galleries, walkways, car parks, machine rooms, false ceilings and raised floors, excluding cooling tower pipes and refrigeration compressor discharge pipes, except when they are within reach of persons.

Point 7 deals specifically with the calculation of the minimum insulation thickness, where either the simplified or the alternative procedure can be chosen. For installations above 70 kW the alternative method should be used.

- Simplified procedure A: in the simplified procedure the minimum thermal insulation thicknesses, expressed in mm, depending on the outside diameter of the uninsulated pipe and the temperature of the fluid in the network and for a material with a reference thermal conductivity at 10°C of 0.040 W/(m-K) must be those indicated in the corresponding tables of RITE.

| Outside diameter (mm) | Maximum fluid temperature (ºC) | ||

| 40…60 | >60…100 | >100…180 | |

| D ≤ 35 | 25 | 25 | 30 |

| 35 < D ≤ 60 | 30 | 30 | 40 |

| 60 < D ≤ 90 | 30 | 30 | 40 |

| 90 < D ≤ 140 | 30 | 40 | 50 |

| 140 < D | 35 | 40 | 50 |

| Outside diameter (mm) | Maximum fluid temperature (ºC) | ||

| 40…60 | >60…100 | >100…180 | |

| D ≤ 35 | 35 | 35 | 40 |

| 35 < D ≤ 60 | 40 | 40 | 50 |

| 60 < D ≤ 90 | 40 | 40 | 50 |

| 90 < D ≤ 140 | 40 | 50 | 60 |

| 140 < D | 45 | 50 | 60 |

| Outside diameter (mm) | Maximum fluid temperature (ºC) | ||

| >-10…0 | >0…10 | >10 | |

| D ≤ 35 | 30 | 25 | 20 |

| 35 < D ≤ 60 | 40 | 30 | 20 |

| 60 < D ≤ 90 | 40 | 30 | 30 |

| 90 < D ≤ 140 | 50 | 40 | 30 |

| 140 < D | 50 | 40 | 30 |

| Outside diameter (mm) | Maximum fluid temperature (ºC) | ||

| >-10…0 | >0…10 | >10 | |

| D ≤ 35 | 50 | 45 | 40 |

| 35 < D ≤ 60 | 60 | 50 | 40 |

| 60 < D ≤ 90 | 60 | 50 | 50 |

| 90 < D ≤ 140 | 70 | 60 | 50 |

| 140 < D | 70 | 60 | 50 |

- The minimum insulation thicknesses of pipe networks in continuous operation, such as domestic hot water networks, shall be those indicated in the tables above increased by 5 mm, as shown in the table below:

| O.D. (mm) | Insulation for DHW pipes | |

| Inside | Outside | |

| D ≤ 35 | 30 | 40 |

| 35 < D ≤ 60 | 35 | 45 |

| 60 < D ≤ 90 | 35 | 45 |

| 90 < D ≤ 140 | 45 | 55 |

| 140 < D | 45 | 55 |

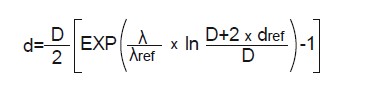

- Simplified procedure B: when using materials with a thermal conductivity other than λref = 0,04 W/(m-K) at 10 °C, the determination of the minimum thickness is considered valid by applying the following equation:

*where:

λref: reference thermal conductivity, equal to 0.04 W/(m-K) at 10 °C

λ: thermal conductivity of the material used, in W/(m-K) at 10 °C

dref: minimum reference thickness, mm

d: minimum thickness of material used, in mm

D: diameter inside of the insulating material, coinciding with the diameter outside of pipe, in mm.

ln: neperian logarithm (base 2.7183…)

EXP: means the neperian number raised to the expression in parenthesis

Installation and maintenance of pre-insulated pipes

Correct installation and maintenance of pre-insulated pipes is crucial in ensuring the efficient and long-lasting operation of the system.

- Preparing the space: Before starting the installation, it is essential to know the site to ensure a smooth installation process and minimise possible mishaps. This involves the identification of pipeline routes, assessment of site conditions and coordination with other work in the area.

- Installation process: The installation of pre-insulated pipes, whether indoors, outdoors or buried, requires meticulous planning and execution.

Indoors, routes are established and pipes are laid ensuring watertight connections and thorough testing to ensure optimal performance. Outdoors, on the other hand, the ground is prepared, pipes are protected against adverse weather conditions and additional layers of insulation are added for durability.

Buried installation, on the other hand, involves proper excavation, properly sloped pipe laying, and thorough sealing and protection to prevent damage and leakage.

In all situations, it is essential to follow local regulations and safety standards to ensure the integrity and efficiency of the system over time.

- Functional testing and adjustment: Once the installation is completed, functional tests are carried out to verify the integrity and efficiency of the system. This may include pressure testing and leak testing to ensure that there are no performance problems. If anomalies are found, adjustments and corrections are made as necessary to ensure optimal operation.

- Preventive maintenance: Regular maintenance is crucial to ensure the long-term performance of pre-insulated pipes. Periodic inspections should be scheduled to identify and address any signs of wear, corrosion or damage. In addition, the manufacturer’s recommendations for replacement or repair of components should be followed as necessary. Additional measures can be implemented in addition to basic maintenance to optimise the performance of the system. This can include the installation of remote monitoring systems to proactively detect problems, as well as the implementation of efficient operating practices to minimise wear and maximise system life.

Technological advances in insulated pipes

Technological advances continue to drive innovation in the design and manufacture of pre-insulated tubes, opening up new possibilities and further improving their efficiency and performance.

Current research is focusing on areas such as new, more thermally efficient insulation materials, intelligent control systems to monitor and optimise performance in real time, and advanced manufacturing techniques that reduce costs and increase the durability of the final product.

Also, other important innovations that are setting trends in the design and manufacture of pre-insulated pipes:

- Development of new exterior coating materials and techniques to improve resistance to corrosion, abrasion and other environmental damage. These coatings not only protect the pipe and the inner insulation, but can also provide additional properties, such as fire resistance or antimicrobial properties, depending on the specific needs of the application.

- Promotion of the most efficient and sustainable insulation solutions. PUR (polyurethane) foams of renewable and recyclable origin are being used, which have a minimal environmental impact. These foams offer excellent thermal performance and can be adapted to a variety of environmental conditions, making them an attractive option for industrial, commercial and urban applications.PUR (polyurethane) foams of renewable and recyclable origin are being used, which have a minimal environmental impact.

When combined with the previously mentioned technological advances in areas such as intelligent control and advanced manufacturing techniques, these improvements are opening up a wide spectrum of possibilities for even more innovative and cost-effective solutions in the piping sector.

Download our ebook

Discover all about pre-insulated pipes: download our free eBook now and dive into the world of advanced piping system solutions. Your complete guide awaits!